Assembly Capabilities

High-volume production with consistent quality

Production Capabilities

Advanced assembly lines designed for high-volume production with consistent quality and precision.

High Volume

Production capacity up to 100,000+ units per month with consistent quality

Precision Control

Automated assembly with ±0.1mm tolerance control and real-time monitoring

Quality Assurance

ISO 9001:2015 certified processes with comprehensive quality control

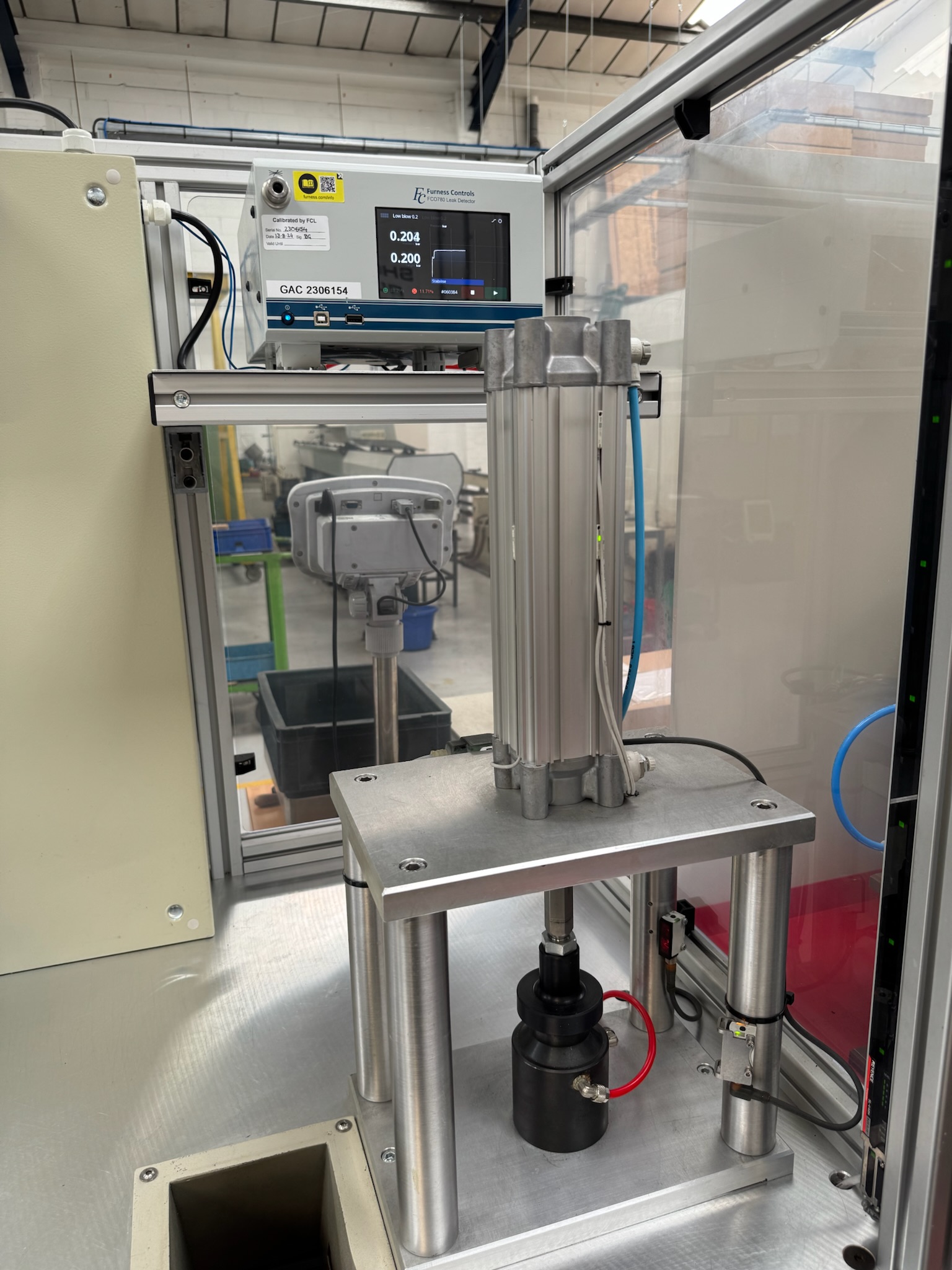

Advanced Assembly Lines

State-of-the-art assembly lines designed for high-volume production with automated quality control and real-time monitoring.

Assembly Products

Steering Rack Assemblies

Complete steering rack assemblies with precision-machined components and quality-tested performance.

- High-strength steel components

- Precision assemblies

- Quality-tested performance

- ISO 9001:2015 certified

Thermostat Assemblies

High-accuracy thermostat assemblies with precision temperature control and reliable performance.

- ±1°C temperature accuracy

- Fast response time < 30 seconds

- Precision-machined components

- Automotive grade reliability

Assembly Process

Systematic approach to high-volume assembly ensuring consistent quality and performance.

Component Preparation

Quality inspection and preparation of all assembly components

Automated Assembly

Precision assembly using automated equipment and quality control

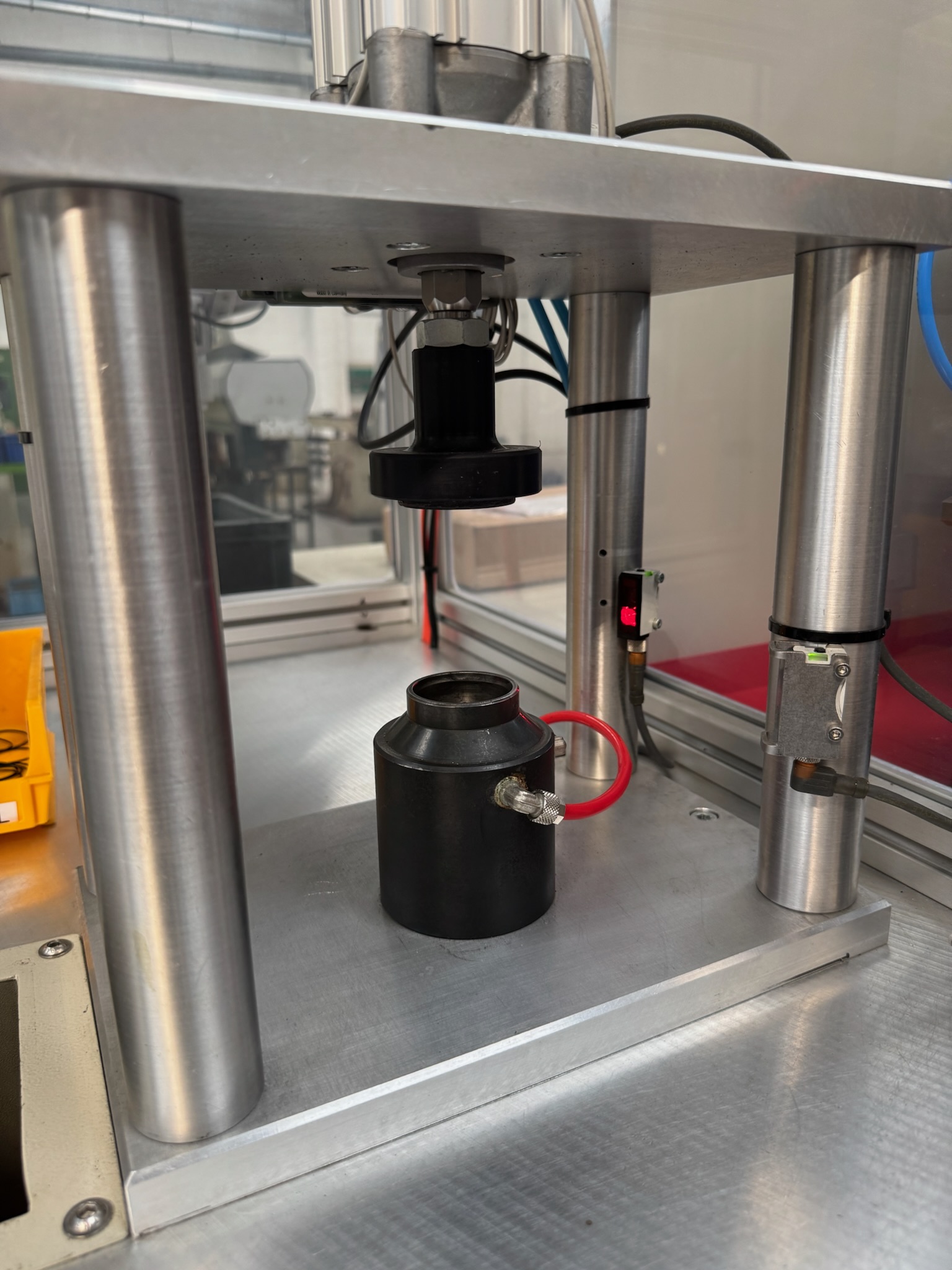

Testing & Validation

Comprehensive testing and validation of assembled components

Final Inspection

Final quality inspection and packaging for shipment